UV printing: State-of-the-art technology for precise and durable photo prints

From the WhiteWall expert Jan-Ole Schmidt

When producing photo prints, wall art, and photo gifts, the various printing techniques play a decisive role in the quality and durability of an image. One of the most modern and effective technologies to have established itself in recent years is UV printing. Originally used in the advertising and graphics industry, this printing process has now also revolutionized photo printing. UV printing not only delivers impressive results in terms of color depth and sharpness, but is also extremely environmentally friendly and durable. But what exactly is UV printing and how does this innovative process work?

Introduction to UV printing

UV printing is based on a special process that uses ultraviolet light. Unlike conventional printing processes, in which the inks dry through evaporation or absorption, UV printing uses a completely different technology. After special UV inks are applied to the substrate to be printed, they are dried by targeted irradiation with ultraviolet light. The light cures the ink in seconds, so that it immediately adheres firmly to the material.

How UV printing works

The UV printing process begins with the application of special UV inks to the desired substrate. Unlike other printing processes, in which the ink penetrates the paper or substrate, UV printing leaves the ink directly on the surface. After the ink has been applied, it is exposed to UV lamps. These lamps emit ultraviolet light, which triggers a chemical reaction in the ink, more precisely in the so-called photoinitiators in the ink. The liquid ink immediately hardens to a solid state.

This rapid curing has several advantages. On the one hand, the printing process can be completed more quickly, as no long drying time is required. On the other hand, the immediate curing results in sharper contours and more detailed prints, as the ink does not run, as can sometimes be the case with conventional printing processes. The result is excellent image quality with vibrant colors and fine details.

Material diversity: UV printing on various surfaces

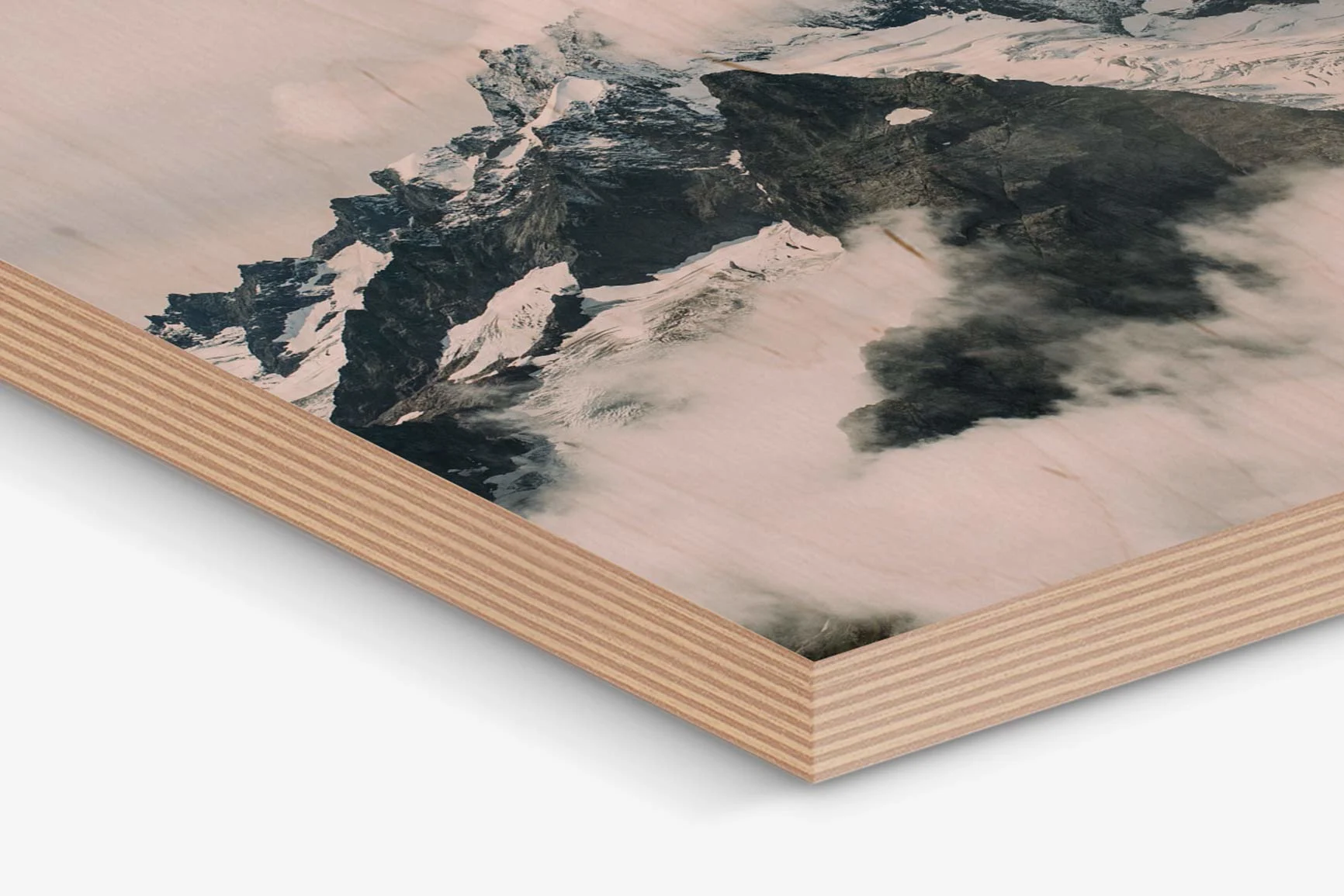

Material diversity: UV printing on various surfaces One of the outstanding features of UV printing is its versatility. The printing process can be used on a wide range of materials that are not suitable for conventional printing processes. In addition to classic paper and cardboard types, plastics, glass, metal, and even wood can be printed on without any problems. This flexibility makes it possible to print photos and designs on materials that are suitable for special applications or decorative purposes. In our WhiteWall range, high-quality UV printing is used, for example, for direct printing on aluminum Dibond, Forex panels, and birch wood.

Thanks to the rapid curing of the ink, the print image remains razor sharp even on smooth surfaces. This makes UV printing particularly interesting for the production of photos on aluminum or other high-quality substrates. The results are impressive: the colors appear strong and vivid, and the prints themselves are extremely robust and durable.

Environmentally friendly UV printing

At a time when sustainability and environmentally conscious behavior are becoming increasingly important, UV printing offers considerable advantages. In conventional printing processes, the ink evaporates during the drying process, often releasing solvents into the air. With UV printing, on the other hand, the ink is cured directly by ultraviolet light, so no harmful vapors are released. In addition, UV printing consumes less energy because no additional drying equipment is required. These factors make UV printing a more environmentally friendly alternative to conventional printing processes.

Durability and resistance of UV prints

Another significant advantage of UV printing is the exceptional durability of the prints. Since the ink cures directly on the surface, it is extremely resistant to external influences. UV prints are weather and moisture resistant. These properties make them ideal for applications where the prints are used outdoors or in humid environments for long periods of time.

UV ink does not fade even when exposed to sunlight, so the colors retain their brightness over a long period of time. This is a decisive advantage over other printing processes, in which the colors can gradually fade when exposed to sunlight. UV printing is therefore suitable not only for indoor but also for outdoor use.

Areas of application for UV printing in photography

Thanks to its excellent image quality and the ability to print on almost any material, UV printing has opened up new creative horizons in photography. This technology is frequently used in the production of large-format photo prints and wall art. Photos on aluminum or metal surfaces appear particularly vivid and brilliant thanks to UV printing. The durability of the prints ensures that the quality of the images is maintained over the long term.

UV printing compared to other printing techniques

UV printing offers numerous advantages over conventional printing methods such as offset or inkjet printing. While offset printing requires large print runs to be economical, UV printing is also profitable for smaller runs or individual items. This makes it particularly interesting for photo production, where individual prints in small quantities are often in demand.

UV printing cures instantly and delivers razor-sharp images. In addition, UV printing can be used to print on special materials such as glass or metal, which is often not possible with inkjet printers.

Future developments in UV printing

UV printing has developed rapidly in recent years and continues to offer new opportunities for the photo and printing industry. The technology is constantly being improved to enable even more precise printing and expand the range of applications. The integration of new UV LED technologies further reduces energy consumption, making the printing process even more environmentally friendly.

Another trend is the expansion of the color spectrum that can be used in UV printing. For example, fluorescent colors can be integrated into the printing process, resulting in even more creative and eye-catching prints. These developments suggest that UV printing will continue to play a central role in photo production in the future.

Conclusion:

If you are looking for a printing technology that combines the highest quality, environmental friendliness, and durability, UV printing is a good choice. Thanks to its fast and precise drying technology, it produces razor-sharp and color-intensive images on a wide range of materials. UV printing offers almost unlimited design possibilities and is suitable for both indoor and outdoor use. Its high durability and environmentally friendly technology make UV printing a forward-looking process that is playing an increasingly important role in modern photography.

Learn more about the author

Jan-Ole Schmidt (better known simply as Ole) comes from northern Germany and has been with WhiteWall for over 11 years. As a team leader in product management, he has more than 15 years of experience in the photography industry. He is self-taught in photography and has built up in-depth expertise in image production, papers, laminating and framing.

His strength lies in the combination of technical expertise and customer perspective - from file upload to framing in the WhiteWall configurator. Ole has held workshops, been a guest on podcasts and is in close contact with the photography community. He lives, works and photographs in Cologne.

WhiteWall Product Recommendations

Also interesting:

Submitted by WhiteWall expert Jan-Ole Schmidt

Inkjet printing: Precision and brilliant colors for high-quality prints

This contactless process offers impressive detail thanks to the finest ink droplets. Discover the advantages of pigment inks and specialized Fine Art papers. Ideal for long-lasting results with maximum color brilliance in gallery quality.

Submitted by WhiteWall expert Jan-Ole Schmidt

Sublimation printing: The innovative way to achieve long-lasting and brilliant images

Gas-phase color transfer anchors motifs directly into materials such as aluminum or textiles. This results in extremely robust, moisture-resistant images with exceptional color brilliance. Learn more about the advantages of sublimation printing for durable wall art.

Submitted by WhiteWall expert Jan-Ole Schmidt

Laminating photos: High-quality protection and an aesthetic finish

Lamination on backing materials such as aluminum Dibond stabilizes images and protects them from UV light and moisture. The process enables a modern, frameless presentation with an impressive depth effect. Learn more about finishing for a professional, gallery-quality finish.